21 cfr part 11 examples.

21 CFR Part 11: FDA and the importance of system validation

For companies operating in the healthcare area and wishing to export their products to the United States, espousing 21 CFR Part 11 is of abecedarian significance. This standard was created by the FDA and aims to regulate the motorized robotization systems of medicinal diligence.

Conforming to 21 CFR Part 11 can be intriguing for numerous diligence, since Anvisa (National Health Surveillance Agency) also has an original standard, RDC301/2019. It’s worth remembering that the quality and safety of the product of companies linked to the health area must be constantly assured, therefore guaranteeing the minimal threat to cases.

For similar control, it’s necessary that the processes meet specific norms of the control bodies throughout the product chain, avoiding any error or violation. Therefore, the two abecedarian points of the 21 CFR Part 11 standard relate to the norms needed for the storehouse of data and electronic autographs and for the entire life cycle of drugs, from development to distribution and trade.

What’s system confirmation?

System confirmation is a step performed with the company that hires or purchases a system. It can be just software, outfit, or both. And it takes place from the original stage — probing for results — to thepost-installation and complete operation stage, where everything needs to be recorded.

Similar records aim for a series of documents to automatically validate the system for the operation that the institution requires. For Anvisa, simply online processes are considered a type of software, and for this reason, they must be validated. This is true indeed if they aren’t installed on any machine.

Therefore, companies in the health sector have decreasingly invested in the robotization of processes and the use of electronic records to replace paper. Similar change guarantees the integrity of the information generated through robotization. In other words, they must always represent reality, unassailable and stored in a secure terrain, in addition to being produced automatically and free from any excrescencies.

Still, to validate the system, it’s necessary to observe if it has some important characteristics, similar as

. Individual access with login;

Word for time control of sessions;

Defended data;

Possibility to copy the data or publish it;

Have a word recovery or change policy that allows for an inspection.

These are essential particulars that need to be in the system. This ensures that the confirmation will be effective.

Qualification of systems

Qualification is an important process when validating systems. It’s the sum of conduct created to document and attest that systems, outfit and installations lead to the anticipated results. Qualification is an integral part of the confirmation process, but the individual way of the qualification process don’t signify the confirmation of a process.

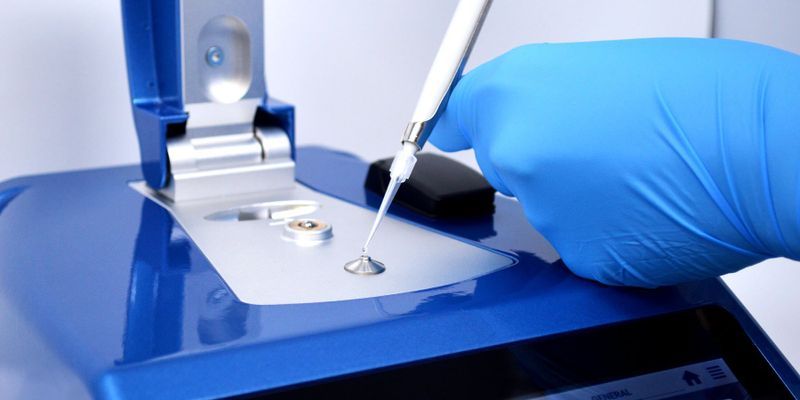

Therefore, to have a controlled process, it’s necessary to validate and qualify the system. And before the confirmation process, the outfit must be authorized and calibrated.

A company’s quality system, to be considered complete, must contain an outfit qualification or process confirmation. In this way, when a qualification is carried out well, it avoids rework and reduces diversions. At the same time, it optimizes time and allows for a nonstop enhancement program to be carried out.

First, before starting the qualification conditioning, it’s over to the director to assess which qualification strategy will be followed. Every company needs to define the path to follow, and this must be recorded in the confirmation master plan (PMV).

For Anvisa, the documents must follow the PMV and must be auditable. In other words, in case of an inspection, these documents must be available, and they are;

.Project Qualification (QP)

The Design Qualification protocol checks all attestation. Its ideal is to dissect if the outfit meets the conditions requested to be installed and operated and if it complies with the stoner specifications (URS- Stoner Conditions Specifications). It also checks if it corresponds to the Good Manufacturing Practices norms needed by the company.

Installation Qualification (QI)

Set of conduct taken to certify and validate that any installations, systems and outfit are duly installed and/ or function rightly. It also checks if they lead to the anticipated results. Qualification is frequently a part of confirmation, but the individual qualification way alone don’t constitute a process confirmation.

Functional Qualification( QO)

Set of operations that establish, under specified conditions, that the system or subsystem operates as anticipated, in all functional ranges considered. All outfit used in performing the tests must be linked and calibrated before being used.

Performance Qualification (QD)

Proved verification that the outfit or system presents harmonious and reproducible performance, in agreement with defined parameters and specifications, for extended ages. In certain cases, the term “ process confirmation” may also be used.