FDA 21 cfr part 11 .

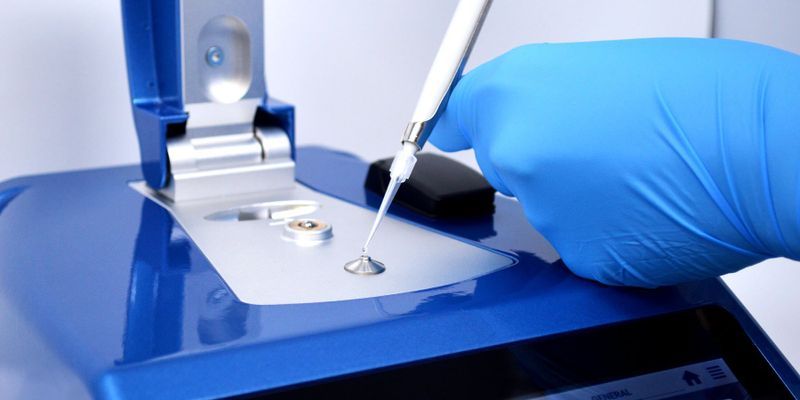

21 cfr part 11 ,Recorder for pharmaceutical companies

The product range of the Finnish company Vaisala has been extended with Veriteq recorders.

The offer includes:

Temperature recorder, SP 1000 series | 1,400 2 to 4 channels

Temperature recorder, DL 1000 series | 1400 from 2 to 4 channels with validation protocol

Temperature recorder with a wide range VL 1016/1416 – a precise 2 or 4 channel recorder designed for ultra-low temperature measurementsveriteq

Temperature and humidity recorders: Vaisala SP 2000 | Vaisala DL 2000

with universal voltage input Vaisala DL4000

FDA 21 cfr part 11 and a series of data loggers designed to work with a wide range of transducers and sensors with a voltage or current output of 0 – 20 mA.

Veriteq loggers are a simple solution for measuring and recording pressure, flow, fluid level, pH, electrical properties, water content and gas concentration data. Perfect for use in standalone network applications or for on-site measurement.

The recorder communicates directly with the computer via USB or via the Ethernet adapter with the existing network. Each recorder contains an internal memory backup battery which stores a wide range of measurement variables. The data loggers work with Vaisala software that enables the download, display and analysis of data and their protection against external modification in accordance with the 21 CFR Part 11 directive. The optional viewLinc © system ensures uninterrupted monitoring and possible alarm 24/7 days a week. Reports are individually configurable and can be exported to Excel and PDF.

Advantages / Benefits

internal battery for 10 years of built-in memory operation

single and multi-channel versions with up to four measuring channels

easily programmable input channels

programmable memory write interval

many communication options – USB, Ethernet, WiFi

optional vNet docking station with built-in PoE and Ethernet output

NIST-compliant calibration

two-year warranty

The recorders work with two types of software; FDA 21 cfr part 11 viewLinc for a continuous monitoring system with a network database or vLog with data recording to a file. The recorders work in autonomous and network applications, they can be connected to a PC via USB cable, Ethernet or WiFi. Each recorder has a memory and built-in batteries with a lifetime of 10 years. Thanks to this, the recorder is resistant to power failure or failure of the communication network.

All recorders can work with the following software:

- viewLinc – universal database software. Vaisala viewLinc, monitoring, alerting and reporting.

As part of the continuous monitoring system, viewLinc provides real-time presentation of trends and their recording in accordance with 21 CFR and Annex 11. ViewLinc monitors temperature, relative humidity, CO 2 , pressure difference, level, door opening status. Cooperates with, among others with: HMT330, HMT140, DMT340, PTU300. Ideal for extensive metering systems or standalone applications, viewLinc uses your existing network, eliminating the cost of installing and maintaining a dedicated network for your continuous monitoring system. The software supports Ethernet, PoE, WiFi.

It offers low operating costs due to easy connection to the existing network, remote access and scalability to thousands of measurement points, security of data records, GxP compliance. Additionally, 24/7 monitoring with automatic alarms via SMS, e-mail. Custom reports can be generated automatically or on demand, created and delivered via email. Option of wireless motion sensors for hard-to-reach places. Optional IQ validation | OQ.

- vLog – software for reading data in two versions with the VL validation protocol and without SP

Vaisala Vlog VL is convenient software with a validation protocol.FDA 21 cfr part 11 Designed for mapping rooms, chambers, etc. with collecting, analyzing and transmitting information from Vaisala VL recorders. The software is easy to use and designed to perform temperature and humidity tests in GxP compliant applications. The software also includes the function of monitoring the validity of calibration certificates for sensors. When there is no need to have validation protocols, you can use the vlog SP version. Compliance with IQ / OQ procedures

The software is available in two versions, SP – standard and VL, extended with GMP 21 CFR Part 11 compliance requirements – logging, viewing and printing of data, plus IQ and OQ validation protocols.

The recorders are available in two versions, SP and VL:

SP version with target recipient not subject to FDA 21 cfr part 11 / GMP requirements. No checksum in files, no reminder about the calibration deadline.

VL for companies subject to FDA 21 cfr part 11 / GMP requirements . Version with a higher level of data encryption, detecting every attempt to change data files and recording every unauthorized attempt to change the calibration data. Additionally, information on the expiry of the calibration validity.

Software features common to SP and VL versions:

Graphics generation (zoom, curve selection, axis modification)

Selection of measured values from the table for printing

Possibility of determining the minimum, maximum and average value – statistical processing

Programmable path for saving data and disk

Create charts and reports from logger files.21 cfr part 11 Additionally, if we use the vlog version of the VL, we can guarantee the security and traceability of the generated charts and reports. Tracking is done via administrative options (security levels), audit trails. These functions help to protect against accidental use of the wrong recorder.

The VL version includes all the features of the SP version plus additionally:

Create safe charts and data files with information about their current status.

User data and security – vLog uses the Windows password for multi-level control of access to the local account. The network administrator is able to share only certain resources, protecting the rest from unauthorized access.

21 cfr part 11 It has a built-in Audit Trail generator containing a clear description of the process from the very beginning to the end, with a description of the method of documenting and controlling the operation.

Data copying function – having programmed recorder settings, we can easily copy it to subsequent recorders.